NanoJet Applications

Concept

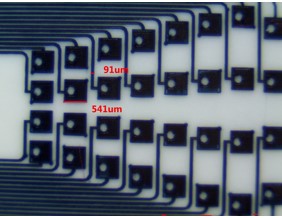

High-Density Interconnects

The focusing ability of the NanoJet Printhead allows printing of interconnect traces with pitch as small as 30 microns for high-density interconnect applications.

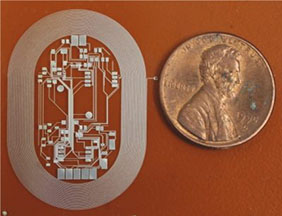

Bioelectronics

IDS’ NanoJet technology can be used for a variety on biomedical applications. Circuits have been printed onto flexible substrates such as liquid crystal polymer (LCP), polyimide and Polyethylene terephthalate (PET). Printed circuits are flexible and can be encapsulated using biocompatible encapsulants such as PDMS or Parylene. The NanoJet technology can be used to print sensors using silver and gold nanoparticle ink.

Conformal Electronics

The NanoJet print technology has a long working distance between the print surface and the print nozzle exit orifice. There is no shutter to limit this distance. The exit jet from the NanoJet printer remains collimated over a long distance (5 mm or greater) and as such printing over features to a few millimeters tall can be done without translating the print head in a vertical direction. The NanoJet print head is very compact and can be easily integrated onto a robotic arm to enable printing that is normal to a nonplanar surface. The high velocity jet maintains a well-controlled trajectory over a long distance which is also enabling for conformal printing.

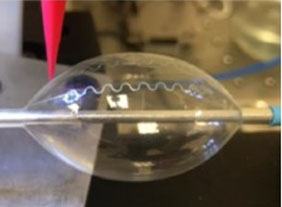

Wireless Power Transfer

Direct Write Inductor Coils

IDS has demonstrated the ability to directly print inductors used for wireless power transfer. Best results have been obtained using high output rate NanoJet print head. Our recently developed process enables coils to be produced with high coupling efficiency and low resistance. High mix, low volume production of coils used in biomedical devices, including implantables.